The RTD is manufactured by winding a wire (wire wound elements) or plating a film (thin film elements) on a ceramic or glass core and sealing the element within a ceramic or glass capsule.

Since the majority of RTDs have low initial resistance, often 100 ohms, and have a small change in resistance per unit of temperature range, the resistance of the lead wire is often compensated for with a three or four wire bridge configuration built into the measuring devices. By selecting the proper elements and protective sheathing, RTDs can operate in a temperature range of (-200 to 650) °C [-328 to 1202] °F.

An RTD is a passive measurement device; therefore, you must supply it with an excitation current and then read the voltage across its terminals. You can then easily transform this reading to temperature with a simple algorithm. To avoid self-heating, which is caused by current flowing through the RTD, minimize this excitation current as much as possible. The easiest way to take a temperature reading with an RTD is using the 2-wire method.

Using the 2-wire method, the t wo wires that provide the RTD with its excitation

current and the two wires across which the RTD voltage is measured are the

same. The inaccuracy using this method is that if the lead resistance in the

wires is high, the voltage measured VO, is significantly higher than

the voltage that is present across the RTD itself. To get a more accurate

measurement, use the 4-wire method.

wo wires that provide the RTD with its excitation

current and the two wires across which the RTD voltage is measured are the

same. The inaccuracy using this method is that if the lead resistance in the

wires is high, the voltage measured VO, is significantly higher than

the voltage that is present across the RTD itself. To get a more accurate

measurement, use the 4-wire method.

The 4-wire method has the advantage of not being affected by the lead resistances because they are on a high impedance path going through the device that is performing the voltage measurement; therefore, you get a much more accurate measurement of the voltage across the RTD.

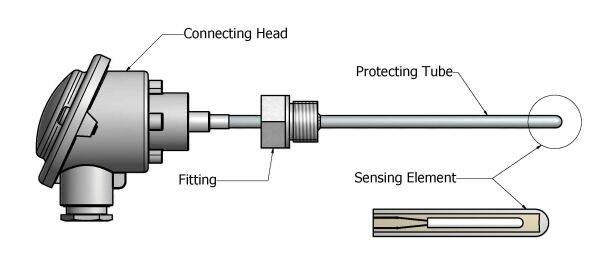

Thermometrics manufactures RTDs for a variety of industry applications.

From single- or dual-element RTDs, to PT100's to Sanitary CIP types,

Thermometrics has the right sensor for your job. If what you need is not

available from our company catalog, our product engineers and sales

staff will design an RTD for your specific application, including

temperature sensor assemblies that require connection heads, thermowells

and/or transmitters.

Thermometrics manufactures RTDs for a variety of industry applications.

From single- or dual-element RTDs, to PT100's to Sanitary CIP types,

Thermometrics has the right sensor for your job. If what you need is not

available from our company catalog, our product engineers and sales

staff will design an RTD for your specific application, including

temperature sensor assemblies that require connection heads, thermowells

and/or transmitters. A Resistor

is a two-terminal electronic component that produces a voltage across

its terminals that is proportional to the electric current passing

through it in accordance with OHM's law.

A Resistor

is a two-terminal electronic component that produces a voltage across

its terminals that is proportional to the electric current passing

through it in accordance with OHM's law.