Bearing Thermocouple Sensors

Bearing Thermocouples are designed for areas where there are space limitations. They are small, compact and are often used to detect temperature increases in bearings, thrust bearing plates, shafts and motor windings. They are miniature low mass sensors which are fast responding. Bearing sensors are manufactured using thin film technology and by design are tip sensitive and vibration resistant. They can be spring loaded into a bearing housing or held in position with a high temperature epoxy resin.

Bearing Thermocouple Applications

•Motor windings

•Bearings

•Shafts

•Thrust plates

•Applications where there is a space limitation

Bearing Thermocouple Attributes

•Tip sensitive thin film technology.

•Fast responding to sudden temperature changes.

•Miniature design. Sizes from 0.125 inch in diameter and 0.30 in length.

•Designed for temperatures to -50 to 260°C (-58 to 500°F)

•Teflon single or double insulated lead wire.

•Optional wear resistant stainless steel braided jacket.

•Available with spring loaded mounting and retaining thrust washer.

•A variety of tip dimensions available to suit a particular application.

•Vibration proof solid design with no moving parts.

•Element encapsulation using high temperature epoxy resin.

•Moisture proof design.

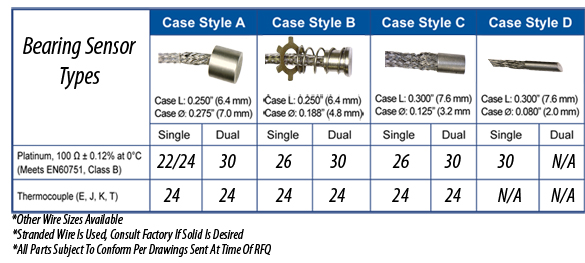

Bearing Thermocouple Specifics

•Thermocouple Type: J, K, T, E

•Measuring Range: -50 to 260°C (-58 to 500°F)

•Case Material: Tin plated copper alloy and Stainless Steel

•Wiring Configuration: 2, 3, and 4 wire (single) 2 or 3 wire (dual)

•Accuracy Range: Class B to DIN EN 60751 Class A to DIN EN 60751

•Tip Construction: Tip sensitive

•Termination: Stranded copper with PTFE insulation; stainless steeloverbraid optional (one sleeve covers all leads).

•Time Constant: 3.0 seconds(case style A) to 1.5 seconds(case style D), typical value in moving water.

•Insulation Resistance: 10 megohms min. at 100 VDC, leads to case.

•Options: Calibration- singlepoint or multiple points

Thermocouples In General

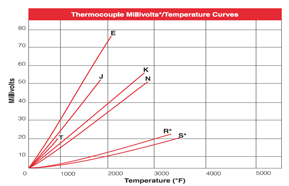

Thermocouples are the most common, convenient, and versatile devices used to measure temperature. They convert units of heat into use able engineering units that serve as input signals for process controllers and recorders. Through selection of appropriate thermocouple wires and sheath components, thermocouples are suitable to be used in temperature ranges from (-200 to 2316) °C [-328 to 4200] °F

A thermocouple consists of a welded 'hot' junction between two dissimilar metals, typically wires - and a reference junction at the opposite ends of the parent materials. Changes in temperature at the measurement junction induce a change in electromotive force (emf) between the other ends. The EMF appears across the free ends of the thermocouple wires where it is measured and converted into units of heat calibration.

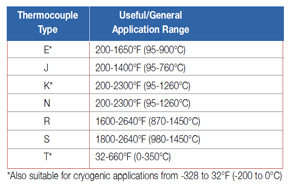

Types of Thermocouples

There are two groups, the base metal thermocouples J, K, T, E and N and the precious metal thermocouples R, S, C and B. Each type has a characteristic (emf) vs. temperature curve and application range. The EMF curve is very dependent on the composition of each conductor. Type J and K are the most widely used in industrial applications. Type J (iron vs. copper-nickel (Constantan)) is versatile in that it can be used in both oxidizing and reducing atmospheres up to 1,400°F. Iron rusts at low temperatures where condensation can form. Type K (nickel-chromium (Chromel) vs. nickel aluminum (Alumel) can be used up to 2,300°F in an oxidizing or inert atmosphere.

Thermometrics produces a wide range of thermocouples for most market applications, including MgO (Magnesium Oxide), industrial and general purpose types. We also produce thermocouple assemblies for hazardous locations and other applications that require connection heads, protection tubes, thermowells and/or transmitters.

Thermocouple Page Links:

Type J Thermocouples

Type K Thermocouples

Type S Thermocouples

Using Your Thermocouples

Comparison of Thermocouples

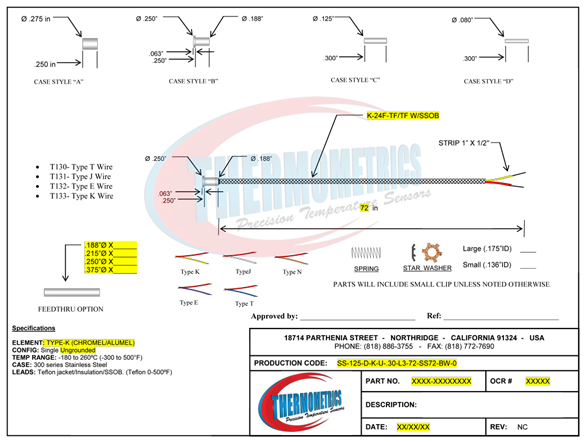

Bearing Thermocouple Specs-

Temperature Range: -50° to 260°C (-58° to 500°F)

Lead Wires: Stranded silver-plated copper conductors with PTFE insulation and optional stainless steel overbraid.

Bearing Thermocouple Configuration Drawings

Thermocouple Type J

Thermocouple Type K

Thermocouple Type S

Thermocouple Type T

|